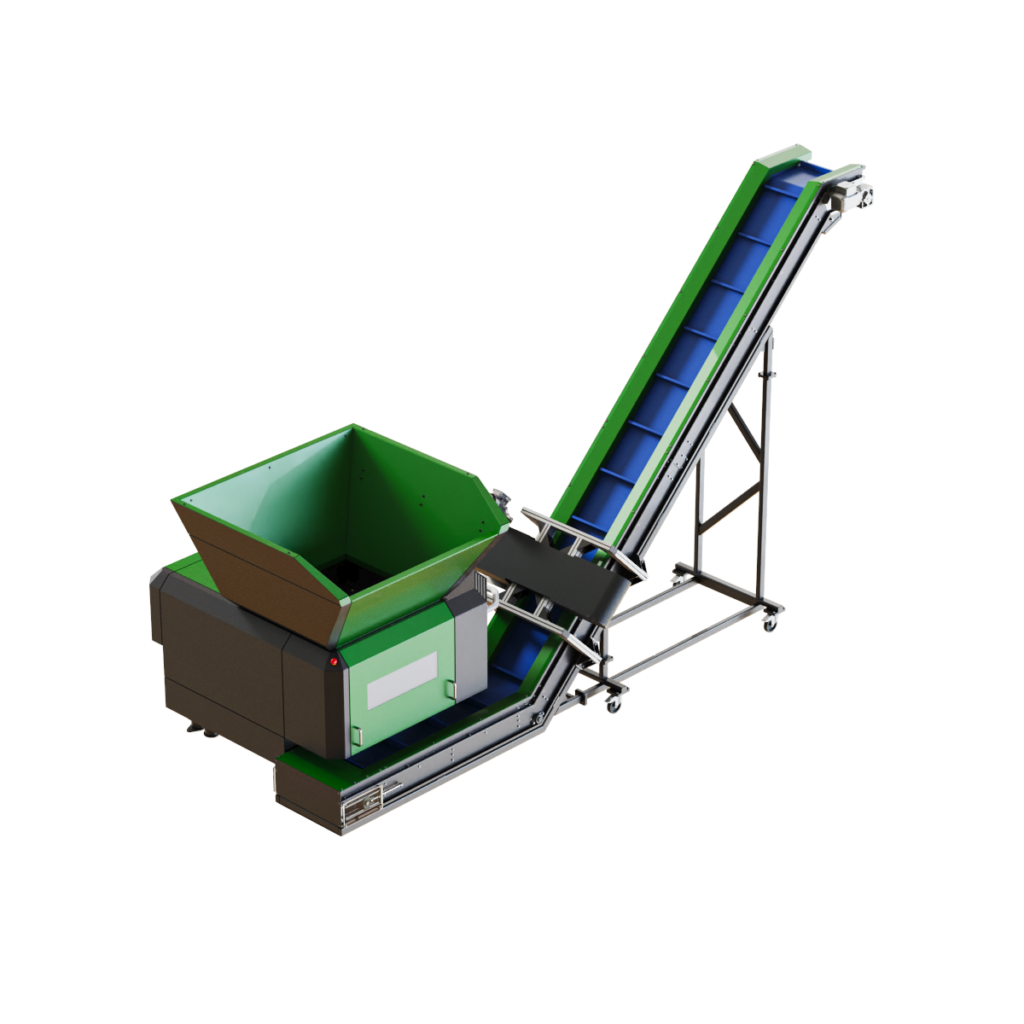

Robust Reuser SD 900 single-rotor universal crusher is a symbol of strength, determination and uncompromisingness.

It works according to its own rules and in perfect harmony with your needs. The minimalist yet striking design gives it a touch of timelessness.

| Motor power (kW) | 18.5 |

| Voltage (V) | 400 |

| Frequency (Hz) | 50 |

| Fuses (A) | Min. 50 |

| Feed hopper opening (mm) | 1446×1565 |

| Filling opening (mm) | 825×870 |

| Volume of the feed hopper (m3) | 0.8 |

| Number of cutting blades | 38 |

| Rotor diameter (mm) | 270 |

| Number of rotors | 1 |

| Working length of the crusher rotor (mm) | 870 |

| Dimensions L/W/H (mm) | 2150×1970×2030 |

| Weight (kg) | 2050 |

| Sieve sizes (mm) | 10/15/16–12/20–15/30–20/30/40/50 |

| Capacity (m3/h)* depends on the sieve size and the type of material | Up to 6.5 |

| Materials suitable for crushing | Waste wood, plastic, paper & cardboard, packaging, agricultural waste |

| Motor power (kW) | 22 |

| Voltage (V) | 400 |

| Frequency (Hz) | 50 |

| Fuses (A) | Min. 63 |

| Feed hopper opening (mm) | 1446×1565 |

| Filling opening (mm) | 825×870 |

| Volume of the feed hopper (m3) | 0.8 |

| Number of cutting blades | 38 |

| Rotor diameter (mm) | 270 |

| Number of rotors | 1 |

| Working length of the crusher rotor (mm) | 870 |

| Dimensions L/W/H (mm) | 2150×1970×2030 |

| Weight (kg) | 2050 |

| Sieve sizes (mm) | 10/15/16–12/20–15/30–20/30/40/50 |

| Capacity (m3/h)* depends on the sieve size and the type of material | Up to 6.5 |

| Materials suitable for crushing | Waste wood, plastic, paper & cardboard, packaging, agricultural waste |

| Motor power (kW) | 30 |

| Voltage (V) | 400 |

| Frequency (Hz) | 50 |

| Fuses (A) | Min. 80 |

| Feed hopper opening (mm) | 1446×1565 |

| Filling opening (mm) | 825×870 |

| Volume of the feed hopper (m3) | 0.8 |

| Number of cutting blades | 38 |

| Rotor diameter (mm) | 270 |

| Number of rotors | 1 |

| Working length of the crusher rotor (mm) | 870 |

| Dimensions L/W/H (mm) | 2150×1970×2030 |

| Weight (kg) | 2050 |

| Sieve sizes (mm) | 10/15/16–12/20–15/30–20/30/40/50 |

| Capacity (m3/h)* depends on the sieve size and the type of material | Up to 6.5 |

| Materials suitable for crushing | Waste wood, plastic, paper & cardboard, packaging, agricultural waste |

Robust Reuser RZC 350 conveyor belt is intended for users who would like to transport the crushed material efficiently and qualitatively from the crushing machine. It is used for the output of crushed material such as wood, plastic, paper, cardboard, aluminum and perfectly matches the crusher of the Robust Reuser SD 700, SD 900, SD 900XL, QD 450 and HD 1500 “Monster“ models. Since on wheels, it is easy to operate. The conveyor belt can be upgraded with an above-belt magnetic separator and a magnetic separator in the drive roller.

ROBUST SD series is a compact, ergonomic and universal line of crushers, suitable for small and medium-sized companies. Drive system with high torque and ReBoost™ function for a superior speed of the push plate enables high capacity with low energy consumption. A large 30l hydraulic unit with the possibility of additional cooling enables high-quality flow and prevents excessive heating of the oil in the hydraulic system. Controlled movement of the hydraulic push plate and reduction of the possibility of material jamming is ensured by the function of segments components called ReMotion™.

Reuser SD series contains ReSmart™ intelligent control system (optional remote access) that enables smart control of the machine.

All or nothing. There be no road between. The value of our brand depends on how much and what uniqueness we can offer you, the users. The Robust brand products have only one goal – to turn your challenge into a solution.

The mission of our forestry equipment and recycling machinery is to exceed your expectations by achieving high productivity, optimization of operating costs and maximum safety .

“More is more!” Our high development orientation is confirmed by six patented solutions that contribute to greater productivity, they maintain toughness and longer lifetime of the machine.

“Save where the result will be visible!” By implementing state-of-the-art software and a selective choice of built-in components with above-average safety and efficiency factors, we – for our costumers – optimize operating costs and guarantee continuous multi-shift operation of forestry machines, crushers and other recycling equipment under the most demanding conditions.

“Safety first!” The safety of you or of your employees is crucial. All our products are manufactured in accordance with safety and health EU guidelines

One of our main strengths is a professional and reliable network of forestry equipment and recycling machinery dealers. The professionally trained staff of our partners around the world ensures the smooth operation of our advanced technologies in the industry of forestry and recycling technology.